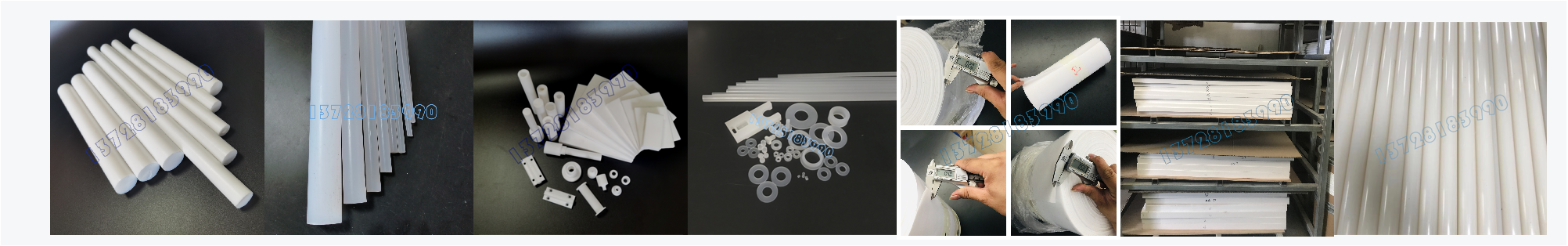

Custom PCTFE Parts:

——High Precision, Extreme Resistance, Safeguarding Your Core Equipment

I. What is PCTFE? — A "Performance Leader" Among High-End Engineering Plastics

PCTFE, namely Polychlorotrifluoroethylene , is a fluoropolymer material polymerized from chlorotrifluoroethylene monomers. While retaining the core advantages of the fluoroplastic family such as chemical resistance and high-temperature tolerance, it makes up for the shortcomings of traditional fluoroplastics (e.g., PTFE) like high processing difficulty and insufficient dimensional stability through its unique molecular structure design, thus becoming a high-end engineering plastic that balances "excellent performance" and "precision molding".

Compared with ordinary plastics, PCTFE not only has the chemical inertness of fluoromaterials but also possesses better mechanical strength and dimensional accuracy. It can be made into custom parts suitable for complex working conditions through CNC precision machining, and is widely used in high-end fields with strict requirements on material performance.

II. Core Properties of PCTFE — Solving Your Industry Pain Points

In fields such as chemical engineering, semiconductors, medical care, and aerospace, ordinary plastic parts often fail frequently due to poor corrosion resistance, insufficient low-temperature tolerance, and substandard precision, leading to equipment downtime, production delays, and even safety hazards. However, with five core properties, PCTFE has become an ideal choice for high-end custom parts:

• Superior Chemical Corrosion Resistance: It can withstand most chemical media such as strong acids (e.g., sulfuric acid, nitric acid), strong alkalis (e.g., sodium hydroxide), and strong oxidants (e.g., hydrogen peroxide). It maintains structural stability in harsh chemical environments, with performance far exceeding that of conventional plastics like PP and PE, effectively preventing part failure due to corrosion.

• Excellent Low-Temperature Performance: It can maintain toughness in an ultra-low temperature environment of -200℃, completely solving the problem of deformation and brittleness of ordinary plastics under extreme temperatures, and is suitable for complex working conditions with alternating high and low temperatures.

• Machinability: It has excellent mechanical processing performance and can be customized into complex structures (e.g., seal rings, valve cores, sensor housings, wafer carriers). Dingfeng has more than 10 years of experience in processing PCTFE parts, and the dimensional accuracy can reach up to ±0.005mm according to different structures.

• Low Friction + Strong Sealing Performance: It has high surface smoothness, with a friction coefficient of only 0.1-0.2 (far lower than that of nylon which is 0.3-0.4). At the same time, it has excellent compression and rebound performance. The seal parts made from it can effectively prevent the leakage of gas and liquid media, improving the operation efficiency of equipment.

III. Industrial Applications of Custom PCTFE Parts — Empowering Efficient Production in Various Fields

Relying on its excellent performance, custom PCTFE parts have become "core supporting components" in many high-end industries, solving technical problems that traditional materials cannot overcome:

• Chemical Engineering Industry: Custom PCTFE corrosion-resistant valve cores, pipe joints, and reactor seal parts can be used continuously for a long time in 30% sulfuric acid and 50% sodium hydroxide solutions without corrosion or leakage, reducing equipment failure rates and cutting down downtime maintenance costs.

• Semiconductor Industry: Precisely processed PCTFE carriers, components, and seals. Currently, Dingfeng provides customization and processing of relevant PCTFE parts for customers in Japan, Germany, Denmark, covering the front-end and back-end processes of semiconductors.

• Aerospace Industry: Dingfeng customizes PCTFE aerospace components for customers, which maintain the precision of parts in an extreme temperature of -200℃ and are suitable for various harsh scenarios.

IV. Our Custom PCTFE Services — End-to-End Exclusive Guarantee from Requirement to Delivery

We have been deeply engaged in the field of PCTFE material processing for more than 10 years, with more than 20 CNC precision machining centers, 5 molding production lines, and a professional material performance testing laboratory. We have built a "full-process custom service system" to free you from worries about part adaptation:

-

Precise Requirement Alignment: Professional engineers communicate with you one-on-one, gain an in-depth understanding of your application scenarios (temperature, medium, pressure, precision requirements), provide material selection suggestions and structural optimization solutions, avoid "over-design" or "insufficient performance", and help you control costs.

-

Rapid Prototype Sampling: Relying on mature processing technology, we can deliver samples in as fast as 3 days. We support dimensional testing (laser diameter gauge, coordinate measuring machine) and performance testing (corrosion resistance, high-temperature tolerance) to ensure that samples meet expectations before mass production.

-

Stable Mass Production: We adopt a standardized production process and are equipped with 3-level quality inspection links (raw material inspection, in-process inspection, full finished product inspection). The delivery cycle of mass orders is shortened to 7-15 days, which can meet the production demand of more than 100,000 pieces per month and guarantee your production plan.

Whether you need small-batch sample verification or stable mass supply, whether your demand is for conventional structures or complex special-shaped parts, we can provide you with cost-effective custom PCTFE solutions.We have obtained certifications such as "High-Tech Enterprise" and "ISO 9001 Quality System Certification", and have been rated as "Excellent Fluoroplastic Processing Enterprise" by the industry association for 10+ consecutive years. Our strength has been recognized by both the market and authoritative institutions.

Get Your Exclusive Custom PCTFE Solution Now!

• Phone: +86-13728183990

Choose us, and choose a custom PCTFE partner with "reliable performance, timely delivery, and worry-free service" to make your equipment more stable and production more efficient!